Pneumatic Parts and Fittings (Melbourne)

Pneumatic parts and fittings in Melbourne are critical for maintaining optimal system performance in industrial automation. However, many businesses in the city face challenges when sourcing the right components for their specific applications.

As Australia’s largest pneumatics distributor, Pneumatics Australia offers an extensive range of top-tier pneumatic products and expert support to help you achieve success in your operations. We understand the importance of having a dependable supplier that can provide you with the pneumatic solutions in Melbourne when you need them.

Our team is dedicated to helping you find the perfect components to suit your unique requirements so that your pneumatic systems operate at peak efficiency. Whether you’re in manufacturing, packaging, or any other industry that relies on compressed air technology, we are your go-to partner for all your pneumatic needs.

How Pneumatic Systems Operate

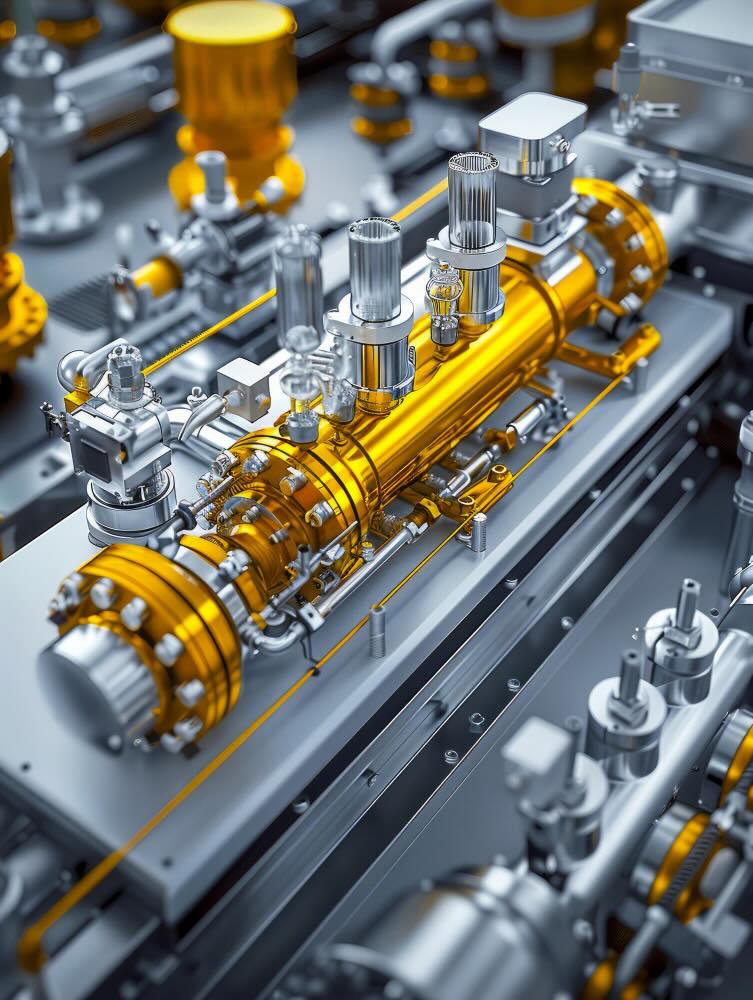

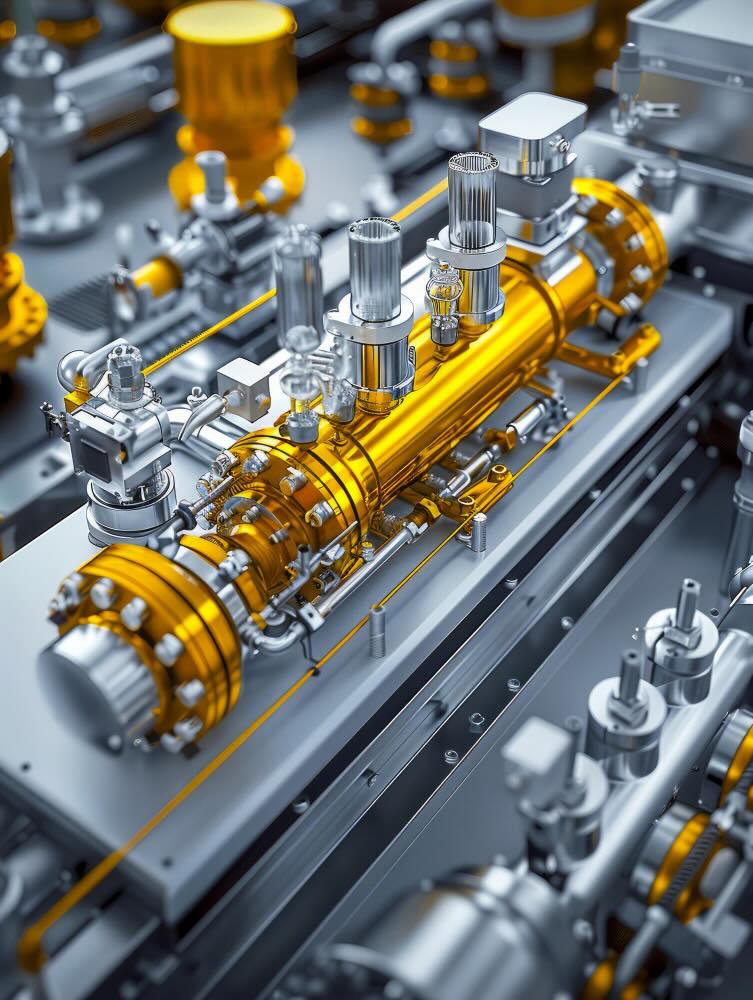

Pneumatic systems use compressed air to transmit power and control motion in various industrial applications. These systems consist of key components that work together to convert compressed air into mechanical energy. These include an air compressor, storage tank, filters, regulators, lubricators, valves, and actuators.

These systems consist of key components that work together to convert compressed air into mechanical energy, including an air compressor, storage tank, filters, regulators, lubricators, valves, and actuators.

The air compressor is responsible for generating the compressed air that powers the system. The compressed air is then stored in an air tank or reservoir, which helps maintain a consistent pressure supply. Filters remove contaminants from the air, while regulators control the pressure to ensure optimal performance. Lubricators introduce oil into the air stream to reduce friction and wear on moving parts.

Valves are used to control the direction, pressure, and flow of the compressed air, directing it to the appropriate actuators. Actuators, such as cylinders, convert the energy of the compressed air into mechanical motion, enabling the system to perform tasks like lifting, pushing, clamping, and much more.

How Pneumatic Systems Operate

Pneumatic systems use compressed air to transmit power and control motion in various industrial applications. These systems consist of key components that work together to convert compressed air into mechanical energy. These include an air compressor, storage tank, filters, regulators, lubricators, valves, and actuators.

These systems consist of key components that work together to convert compressed air into mechanical energy, including an air compressor, storage tank, filters, regulators, lubricators, valves, and actuators.

The air compressor is responsible for generating the compressed air that powers the system. The compressed air is then stored in an air tank or reservoir, which helps maintain a consistent pressure supply. Filters remove contaminants from the air, while regulators control the pressure to ensure optimal performance. Lubricators introduce oil into the air stream to reduce friction and wear on moving parts.

Valves are used to control the direction, pressure, and flow of the compressed air, directing it to the appropriate actuators. Actuators, such as cylinders, convert the energy of the compressed air into mechanical motion, enabling the system to perform tasks like lifting, pushing, clamping, and much more.

Advantages Over Other Types of Automation Systems

Cost-effectiveness:

Pneumatic components are generally less expensive than their hydraulic or electric counterparts, making them a cost-efficient solution for many applications.

Reliability:

Pneumatic systems are known for their durability and long service life, even in harsh environments. They require minimal maintenance and are less susceptible to damage from overloading.

Safety

Compressed air is a clean, safe, and non-flammable power source, making pneumatic systems suitable for use in hazardous or explosive environments.

Simplicity:

Pneumatic systems are relatively simple to design, install, and maintain compared to other automation technologies. They have fewer moving parts, which reduces the risk of failure and simplifies troubleshooting.</p?

Speed and precision:

Pneumatic actuators can provide quick and accurate movements, making them ideal for high-speed, repetitive tasks.

These benefits make pneumatic automation an attractive option for industries such as manufacturing, packaging, food processing, and more.

Advantages Over Other Types of Automation Systems

Cost-effectiveness:

Pneumatic components are generally less expensive than their hydraulic or electric counterparts, making them a cost-efficient solution for many applications.

Reliability

Pneumatic systems are known for their durability and long service life, even in harsh environments. They require minimal maintenance and are less susceptible to damage from overloading.

Safety:

Compressed air is a clean, safe, and non-flammable power source, making pneumatic systems suitable for use in hazardous or explosive environments.

Simplicity:

Pneumatic systems are relatively simple to design, install, and maintain compared to other automation technologies. They have fewer moving parts, which reduces the risk of failure and simplifies troubleshooting.

Speed and precision:

Pneumatic actuators can provide quick and accurate movements, making them ideal for high-speed, repetitive tasks.

These benefits make pneumatic automation an attractive option for industries such as manufacturing, packaging, food processing, and more.

Our Extensive Range of Pneumatic Parts

We offer a wide selection of top-quality pneumatic parts to keep your systems running at peak performance.

Air Compressors

The heart of any pneumatic system, air compressors convert electrical energy into kinetic energy by compressing ambient air to a higher pressure.

We carry a variety of compressors from leading manufacturers, including piston, rotary screw, and scroll types, to suit different application requirements and budgets.

Air Tanks / Reservoirs

Air tanks or reservoirs store the compressed air generated by the compressor, providing a stable supply of air to the rest of the system.

Our tanks are available in various sizes and materials, such as steel and aluminium, to accommodate different system capacities and environmental conditions.

Air Filters

Air filters remove contaminants, such as dust, dirt, and moisture, from the compressed air before it enters the system.

This helps protect downstream components from damage and ensures consistent performance. We offer a wide range of filters with different filtration ratings and capacities to suit your specific needs.

Pressure Regulators

Pressure regulators control the pressure of the compressed air supplied to the system, ensuring that it remains within a desired range. This is critical for maintaining consistent performance and preventing damage to components.

Our regulators are available in various sizes and configurations, with features such as adjustable pressure settings and built-in gauges.

Lubricators

Lubricators introduce a fine mist of oil into the compressed air stream to lubricate moving parts in the system, such as valves and cylinders.

This helps reduce friction, prevent wear, and extend the life of components. We carry lubricators with different oil capacities and flow rates to match your system requirements.

Gauges

Gauges provide visual indication of the pressure, temperature, or flow rate of the compressed air in the system.

This allows you to monitor system performance and detect any issues before they cause damage or downtime. Our selection includes a variety of gauge types and sizes, with features such as easy-to-read dials and durable construction.

Our Extensive Range of Pneumatic Parts

We offer a wide selection of top-quality pneumatic parts to keep your systems running at peak performance.

Air Compressors

The heart of any pneumatic system, air compressors convert electrical energy into kinetic energy by compressing ambient air to a higher pressure.

We carry a variety of compressors from leading manufacturers, including piston, rotary screw, and scroll types, to suit different application requirements and budgets.

Air Tanks / Reservoirs

Air tanks or reservoirs store the compressed air generated by the compressor, providing a stable supply of air to the rest of the system.

Our tanks are available in various sizes and materials, such as steel and aluminium, to accommodate different system capacities and environmental conditions

Air Filters

Air filters remove contaminants, such as dust, dirt, and moisture, from the compressed air before it enters the system.

This helps protect downstream components from damage and ensures consistent performance. We offer a wide range of filters with different filtration ratings and capacities to suit your specific needs.

Pressure Regulators

Pressure regulators control the pressure of the compressed air supplied to the system, ensuring that it remains within a desired range. This is critical for maintaining consistent performance and preventing damage to components.

Our regulators are available in various sizes and configurations, with features such as adjustable pressure settings and built-in gauges.

Lubricators

Lubricators introduce a fine mist of oil into the compressed air stream to lubricate moving parts in the system, such as valves and cylinders.

This helps reduce friction, prevent wear, and extend the life of components. We carry lubricators with different oil capacities and flow rates to match your system requirements.

Gauges

Gauges provide visual indication of the pressure, temperature, or flow rate of the compressed air in the system.

This allows you to monitor system performance and detect any issues before they cause damage or downtime. Our selection includes a variety of gauge types and sizes, with features such as easy-to-read dials and durable construction.

Quality Pneumatic Fittings We Offer

We are your one-stop shop for all the pneumatic fittings you need to build, maintain, and optimise your systems.

Push-In Fittings

Push-in fittings provide a quick and easy way to connect tubing and hoses to other components in the system. They feature a simple push-to-connect design that allows for fast installation and removal without the need for tools.

Our push-in air fittings are available in a variety of sizes and materials, such as brass and composite, to suit different tube diameters and pressure ratings.

Threaded Fittings

Threaded fittings use a male or female thread to create a secure, leak-tight connection between components. They are commonly used to connect pipes, valves, and other threaded components in the system.

We carry a range of threaded fittings in different sizes, materials, and thread types, such as NPT, BSPT, and metric, to match your system requirements.

Quick-Disconnect Couplings

Quick-disconnect couplings allow for fast and easy connection and disconnection of hoses and tools in the system. They consist of two parts: a plug and a socket, which can be connected or disconnected with a simple push or pull action.

Our quick-disconnect couplings are available in various sizes, materials, and valve configurations to suit different flow rates and pressure ratings.

Manifolds

Manifolds provide a compact and efficient way to distribute compressed air to multiple branches in the system. They consist of a single inlet port and multiple outlet ports, which can be individually controlled using valves or regulators.

We offer a selection of manifolds in different sizes, materials, and configurations to suit your specific system layout and requirements.

Tubing / Hoses

Tubing and hoses are used to transport compressed air between the various components in the system. They are available in different materials, such as polyurethane, nylon, and rubber, to suit different pressure ratings, temperature ranges, and chemical compatibilities.

Our selection includes a range of sizes and colours to meet your specific application needs.

Compression Fittings

Compression fittings provide a secure and reliable connection between tubing and other components in the system. They consist of a body, a ferrule, and a nut, which compress the tubing as the nut is tightened, creating a leak-tight seal.

We carry compression fittings in various sizes and materials, such as brass and stainless steel, to suit different tube diameters and pressure ratings.

Choosing the Right Pneumatic Parts and Fittings in Melbourne

When selecting pneumatic parts and fittings for your system, there are several key factors to consider to ensure optimal performance, reliability, and safety:

1. Pressure rating - Make sure that the components you choose are rated for the maximum pressure that your system will operate at. Using components with insufficient pressure ratings can lead to leaks, failures, and safety hazards.

2. Material compatibility - Consider the materials of the components and their compatibility with the fluids and environments they will be exposed to. Some materials may degrade or corrode when exposed to certain chemicals or temperatures, leading to premature failure.

3. Size and configuration - Ensure that the components you select are the correct size and configuration for your system layout and requirements. Mismatched or incorrectly sized components can result in poor performance, leaks, and damage to the system.

4. Flow rate - Choose components that are capable of handling the required flow rate of your system. Insufficient flow capacity can lead to pressure drops, reduced performance, and increased energy consumption.

5. Quality and reliability - Invest in high quality components from reputable manufacturers to ensure long-term reliability and performance. Cheap or poorly made components may save you money upfront but can cost you more in the long run due to frequent failures and downtime.

Our expert sales team can provide guidance on the best components for your specific application, taking into account factors such as pressure rating, material compatibility, and system layout. We can also help you optimise your system design to maximise efficiency, reliability, and performance.

Can I Mix and Match Pneumatic Products From Different Manufacturers?

While it is possible to use products from different manufacturers in your pneumatic system, it is essential to ensure compatibility in terms of thread types, sizes, and pressure ratings. Mixing and matching components can also make troubleshooting and maintenance more challenging.

We recommend consulting with our experts to ensure proper integration and optimal performance.

What Materials Are Best Suited for My Application?

Selecting the ideal materials for your pneumatic parts and fittings depends on the unique requirements of your application, such as operating temperature range, chemical compatibility, and environmental conditions. Some commonly used materials include brass, stainless steel, nylon, and polyurethane.

We can guide you in choosing the most suitable materials for your specific needs, taking into account factors like durability, corrosion resistance, and cost-effectiveness.

How Often Should I Replace My Pneumatic Components?

The optimal replacement frequency for your pneumatic components is influenced by several factors, including the operating environment, the quality of the components, and the level of maintenance performed.

As a general guideline, it is advisable to regularly inspect your pneumatic system for any signs of wear, leaks, or damage and replace components as necessary.

For more specific replacement intervals, consult with our team or refer to the manufacturer's recommendations.

How to Troubleshoot Common Issues With Pneumatic Components?

If you experience issues with your pneumatic system, such as air leaks, erratic performance, or component breakdown, consider the following troubleshooting steps:

- Examine fittings and tubing for any signs of damage or loose connections, and replace if necessary

- Confirm that the system pressure and flow rates are operating within the recommended range.

- Assess valves and actuators for indications of wear or malfunction

- Ensure the air filter and lubricator are functioning optimally

- Inspect the system for contaminants, and clean or replace affected components as needed

If the problem persists, reach out to the experts at Pneumatics Australia for assistance in identifying and resolving the issue.

Can I Mix And Match Pneumatic Products From Different Manufacturers?

While it is possible to use products from different manufacturers in your pneumatic system, it is essential to ensure compatibility in terms of thread types, sizes, and pressure ratings. Mixing and matching components can also make troubleshooting and maintenance more challenging.

We recommend consulting with our experts to ensure proper integration and optimal performance.

What Materials Are Best Suited For My Application?

Selecting the ideal materials for your pneumatic parts and fittings depends on the unique requirements of your application, such as operating temperature range, chemical compatibility, and environmental conditions. Some commonly used materials include brass, stainless steel, nylon, and polyurethane.

We can guide you in choosing the most suitable materials for your specific needs, taking into account factors like durability, corrosion resistance, and cost-effectiveness.

How Often Should I Replace My Pneumatic Components?

The optimal replacement frequency for your pneumatic components is influenced by several factors, including the operating environment, the quality of the components, and the level of maintenance performed.

As a general guideline, it is advisable to regularly inspect your pneumatic system for any signs of wear, leaks, or damage and replace components as necessary.

For more specific replacement intervals, consult with our team or refer to the manufacturer’s recommendations.

How to Troubleshoot Common Issues With Pneumatic Components?

If you experience issues with your pneumatic system, such as air leaks, erratic performance, or component breakdown, consider the following troubleshooting steps:

- Examine fittings and tubing for any signs of damage or loose connections, and replace if necessary

- Confirm that the system pressure and flow rates are operating within the recommended range.

- Assess valves and actuators for indications of wear or malfunction

- Ensure the air filter and lubricator are functioning optimally

- Inspect the system for contaminants, and clean or replace affected components as needed

If the problem persists, reach out to the experts at Pneumatics Australia for assistance in identifying and resolving the issue.

Contact Us for Additional Information

As industries continue to embrace automation, the role of pneumatic products in driving efficiency, precision, and productivity has never been more critical.

Pneumatics Australia is uniquely positioned to help you improve your operations, increase your profitability, and stay ahead of the competition. With our extensive range of premium components, expert support, and customised solutions, we enable your systems to operate with greater efficiency and reliability.

Contact us today to discuss your requirements and discover how our pneumatic solutions can take your business to the next level.